Industrial Graphite Sales with the introduction of its SPLASMA TOOL™ line of Graphite Parts is proud to be the first Graphite Company to focus on the Spark Plasma Sintering Industry.

IGS is excited to now offer a full line of Punch and Die Sets or any other Parts or Components, made to your specifications, to supply your Spark Plasma Sintering needs.

Call or Email us today to see how we can help you!

Advantages

- Shorter process cycle times

- Lower sintering temperatures

- 30 to 40% less energy consumption

- Retain nanograin micro-structure

- Ease of use

- Powder to part net and near net shapes

Applications

- Body armour and defense

- Fuel Cell

- Infrared windows

- Cutting tools

- Turbine power

- Ultra hi-temp ceramic tiles for use by Nasa and the US Airforce

|

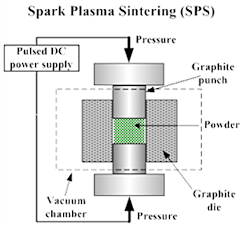

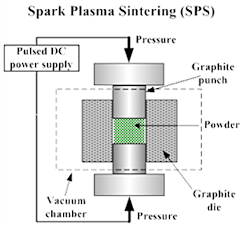

Spark Plasma Sintering (SPS)

– also referred to as Field Assisted Sintering Technology (FAST) or Pulsed Electronic Current Sintering (PECS) – is a revolutionary and cutting edge process that compacts fully dense bodies from metal powders, composites, alloys and ceramics in a shorter time, at higher temperatures and with the finest nanograin micro-structure.

These Sintering Machines (which are manufactured in Japan, Germany and here in the USA) apply three major variables concurrently: temperature, pressure and high density current during compaction. The Graphite Tooling that is used in this process is an integral part of the SPS operation. Not only do the Graphite Parts conduct electricity but they must be of the highest compressive strength and thermal conductivity to withstand the entire process. Accurate precision machining of the graphite punches and dies is critical because fit is imperative.

Industrial Graphite Sales understands this technology and has worked closely with several prestigious Research Departments such as Penn State University in developing the best tooling possible for this fast growing industry. Take advantage of our own research and see how we can help you! |

|